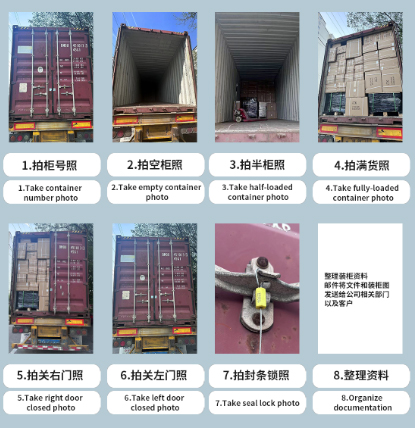

A picture gives you a quick understanding.

1.Take container number photo

Verify consistency of the packing list. Photograph inner container numbers to confirm they match external numbers. Take photos after verification.

2.Take empty container photo

Inspect container condition and photograph empty container. Confirm cargo quantity accuracy before loading.

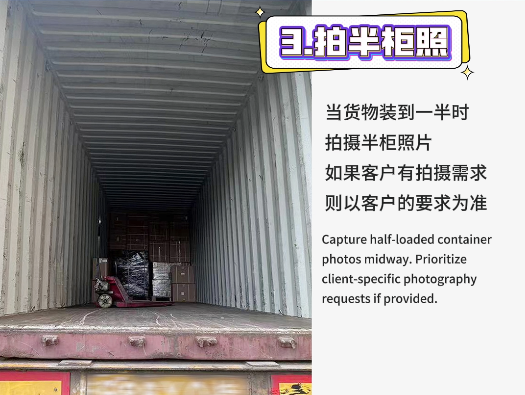

3.Take half-loaded container photo

Capture half-loaded container photos midway. Prioritize client-specific photography requests if provided.

4.Take fully-loaded container photo

Document fully loaded container status with comprehensive photos after completion.

5.Take right door closed photo

Photograph right door closure showing clear cargo arrangement and door details.

6.Take left door closed photo

Record left door closure and capture full container shots with both doors secured.

7.Take seal lock photo

Photograph seal installation emphasizing legible seal number visibility.

8.Organize documentation

Compile loading documentation (including loading diagram) and distribute via email to company departments and client.

Matters need attention:

1. Ensure that the license plate number and cabinet number of the container are consistent with the predetermined information;

2 There must be no light leakage or damage inside the container;

3. Complete cabinet loading as quickly as possible to avoid overtime expenses;

4 Fill in relevant information in time.